Types of Silicon Solar Cells

November 7, 2025

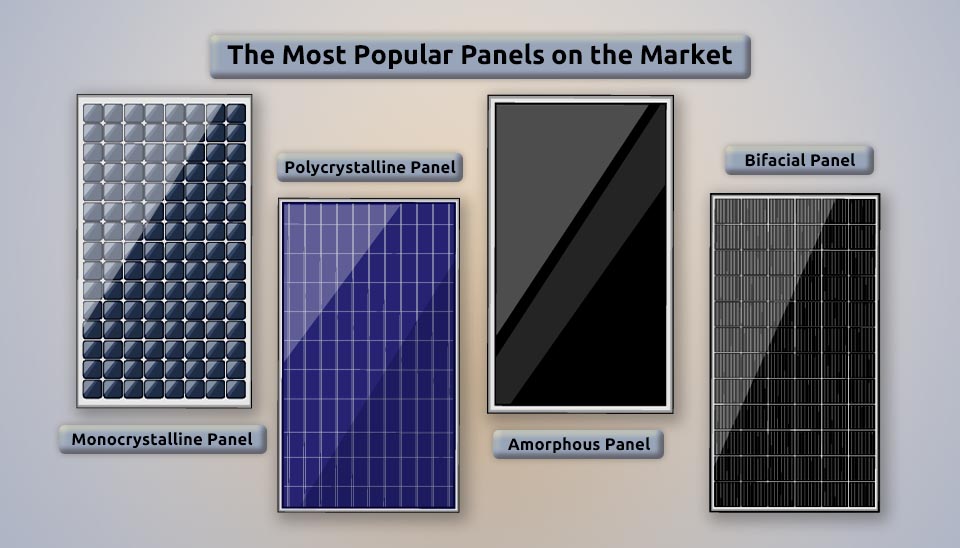

energy is one of the cleanest energy sources, and it has captured global attention. Among these, silicon solar cells dominate over 90 percent of the world market of solar panels and are considered to be the backbone of the solar energy industry (Francoria & Groesser, 2021). This leadership is majorly attributed to the fact that silicon solar cells have many advantages such as scalability, established reliability and constant efficiency enhancement. From residential homes to massive power plants, these cells have paved the way for humanity’s move toward clean energy. These types of cells are classified according to their structure and manufacturing process as monocrystalline silicon, polycrystalline silicon, and amorphous silicon (Badawy, 2015). In addition, there has been the introduction of a new generation of advanced silicon-based technologies, such as PERC cells and cells that collect sunlight both from the front and the back surfaces (bifacial cells), in recent years (Pastuszak & Wegierek, 2022). Choice of any of the above technologies depends on such variables as the size of the project, funds available, and the desired efficiency (Rauschenbach, 2012). You can have a simple comparison of various silicon solar cell technologies in the table above. This article reviews the main types of silicon solar panels, their operational mechanisms, and discusses the advantages and disadvantages of silicon solar cells in modern energy applications

Table 1. Principal Silicon Solar Panels Technologies and their main characteristics Solar

| No. | Type | Description |

| 1 | Monocrystalline Silicon | The single crystal of the pure silicon is high performance and can be used under different

conditions of light, however, it is relatively expensive and sensitive to shade. |

| 2 | Polycrystalline Silicon | These are made up of several silicon crystals and cost less to produce, medium efficiency, and

poor performance at high temperatures. |

| 3 | Amorphous Silicon | A thin-film technology with low production cost, lightweight, and good performance under

diffused light; however, it suffers from low efficiency and faster degradation over time. |

| 4 | Advanced Silicon Technologies (e.g., PERC & Bifacial) | Improved efficiency through rear passivation (PERC), dual-side generation (bifacial), or high

potential from tandem structures (perovskite/silicon). Higher cost or stability issues, but superior energy yield. |

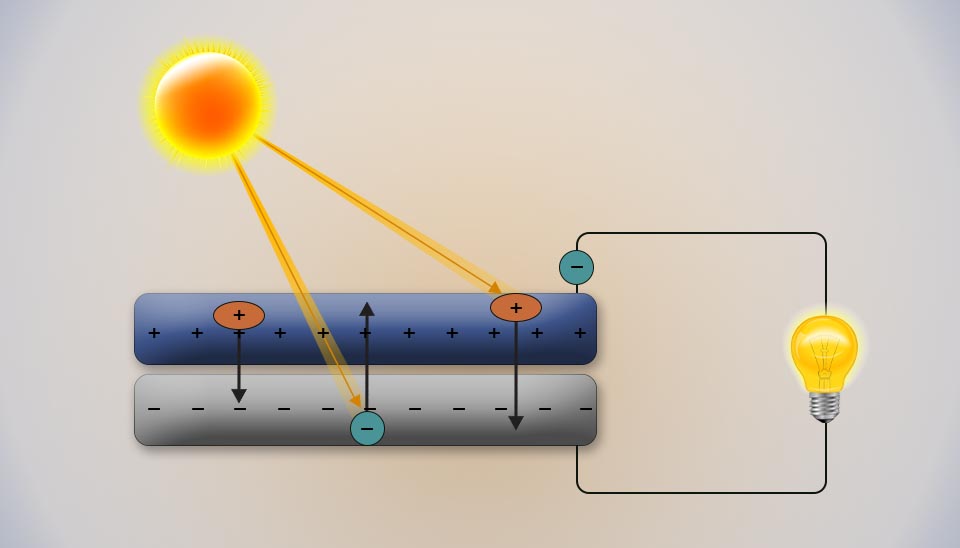

1. How Silicon Solar Cells Work

A silicon solar cell is one of the most common clean energy technologies. It transforms light into di1rect current electrical power (DC) through the so-called photovoltaic effect. A solar panel acts as a diode, i.e., as an electronic circuit in which the electric charge can move in one direction but not in the other (Krisciunas, 2023). To achieve this, semiconductors in the cells are usually doped to create a P-N junction that establishes an internal electric field. Of many semiconductor materials, the development history of silicon has reached 50 years (Chen, 2014). So, in a silicon solar cell, you have a positively doped side of silicon (p-type), which lacks an abundance of electrons, and a negatively doped side (n-type), which is excessively electron-doped. When the sun shines on it, photons dump their energy on the silicon atoms by knocking electrons loose. The internal electric field at the P–N junction separates these charges so formed: electrons are pushed towards the negative electrode, and holes are pushed towards the positive electrode. If a closed conducting circuit encompasses both electrodes, this transfer of charges is accompanied by an electric current that can be used to power electrical appliances (Scharf, 1960). That’s how the PV effect operates in a solar cell.

2. Types of Silicon Solar Cells

Photovoltaic cells that are employed worldwide are predominantly silicon-based solar cells. There are various kinds, which each have their pros and cons in terms of price, productivity, and lasting power. The following subsections give a general overview of the key types of solar silicon cells such as the monocrystalline, polycrystalline, and amorphous silicon, as well as some of today’s advanced silicon technologies.

2.1. Monocrystalline Silicon Solar Cells

Monocrystalline panels are widely regarded among the Best silicon solar cells for residential and commercial systems because they deliver high efficiencies and strong temperature stability (Celadyn & Filipek, 2020). The monocrystalline method represents about 84% of overall crystalline silicon (c-Si) production (Oni & Mohsin, 2024). Each of these solar panels consists of multiple solar cells, with each cell manufactured from a single silicon crystal (Shruti & Kamlesh, 2015). Monocrystalline cells achieve the efficiency of silicon solar cells between approximately 18% and 23%, but ongoing technological breakthroughs and successive optimizations are able to lift that range even higher still. SunPower Corporation, for instance, has achieved modules with a breathtaking yield of up to 22.7%, as testament to the vast potential of this particular technology.

2.1.1. The Monocrystalline Cell Manufacturing Process

The Czochralski process is used extensively to make good-quality monocrystalline solar cells, which are among the best silicon solar cells available today. It is the process that was invented by Jan Czochralski, a Polish scientist. In the Czochralski process, a very pure silicon ingot is molten in a furnace. A silicon crystal seed is slowly dipped down into the melt. When the core touches the melt, crystallization starts, and the monocrystalline silicon crystal development commences (Yang, 2017). Controlling the temperature and rotation rate precisely is essential to growing the crystal slowly and uniformly. When the ingot is rotated, the silicon crystal starts developing around the seed and gradually becomes thicker over it. It may take some days or even weeks for the ingot to grow to the desired size, but at the end, it results in developing perfectly sized single silicon crystal ingots of the furnace (Vegad & Bhatt, 2014).

2.1.2. Advantages of the Monocrystalline

The Czochralski process’s primary benefit is that it is capable of making very high-quality silicon crystal with a regular, ordered crystal structure. It is that ordered structure that gives superior electrical properties and thermal stability to the silicon crystal, and that is very essential for the solar cells for maintaining the performance and silicon solar panel lifespan in terms of delivering power (Sabatino & Hendawi, 2024).

2.1.3. Disadvantages of the Monocrystalline

One of the drawbacks of using the Czochralski process is that making a big, single crystal can be too costly. The processing precision and temperature control necessary to grow superior-quality silicon crystals require highly advanced and expensive equipment. It is for that reason that the monocrystalline silicon solar cells are often more costly than their multicrystalline version (Sabatino & Hendawi, 2024).

2.2. Polycrystalline Silicon Solar Cells

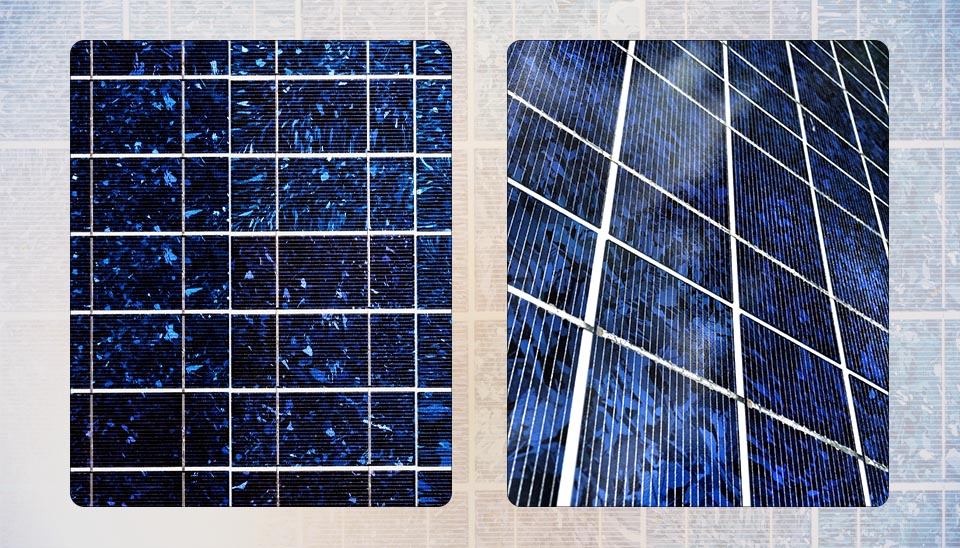

Polycrystalline (also termed multicrystalline) solar cells consist of multiple smaller silicon crystals fused. These cells are produced relatively cheaply by cooling molten silicon in a graphite shape. Panels of this material once made up the cheapest option of home solar power system installation, offering affordability while compromising the efficiency of silicon solar cells by only a small margin. The panels’ efficiency typically falls in the range of 15% to 20% (Sharma & Mishra, 2025).

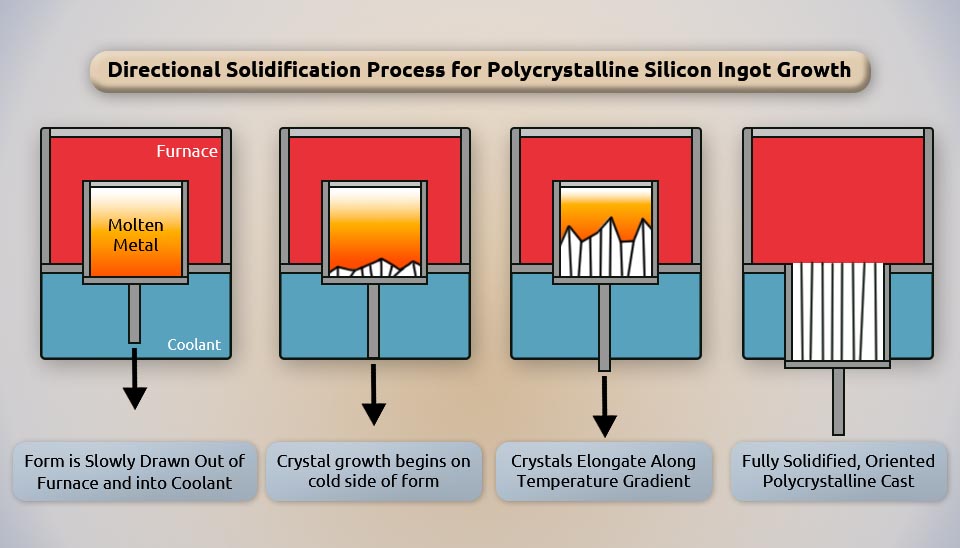

2.2.1. The Polycrystalline Cell Manufacturing Process

The low cost of producing polycrystalline silicon cells mainly comes from the fabrication method known as block smelting. This method unlike the monocrystalline process does not involve the extraction stage to form ingots. Instead, melted high-purity silicon is cast in a square form in the SiO/SiN graphite crucible mold. Then, it is followed by a well-controlled cooling (called directional solidification) that leads to the formation of a block of polycrystalline silicon (Mesquita et al., 2019). Once the block is in place, it’s sliced into square wafers for solar cell production.

2.2.2. Advantages of the Polycrystalline

One of the main merits of this technique is the low price. Since wafers are square in nature, they need not be edge-cut, thus maintaining the perfect geometry for an efficient module assembly. This minimizes wastage of material and optimizes usage of space in a solar module. This less complex manufacturing also lowers the price of the cost, which contributes to polycrystalline solar cells being more appropriate in massive use (Mesquita et al., 2019).

2.2.3. Disadvantages of the Polycrystalline

The problem with this process is that silicon reacts with the graphite crucible. As the polycrystalline silicon is allowed to contact the crucible walls, the impurities eluted from the crucible are liable to permeate into the silicon block. For this reason, the efficiency of silicon solar cells made from polycrystalline material is generally lower than that of monocrystalline cells. Furthermore, their overall heterogeneous appearance, often referred to as a mottled blue color, can change depending on the type of antireflection (AR) coating applied. The irregular bluish surface, which is placed on the material, not only reduces its aesthetic appeal but can also slightly affect light absorption efficiency (Mesquita et al., 2019).

2.3. Amorphous Silicon (a-Si) Solar Cells

Amorphous silicon (a-Si) is one of the main thin-film PV technologies applied in the current solar market. Unlike crystalline silicon, this material has no organized crystal structure and is instead deposited as a very thin layer on various substrates, including glass, plastic, and even metal (Richhariya & Kumar, 2020). a-Si panels, with this special construction, are much lighter and more flexible, and most times, they are also cheaper to manufacture (Shi & Guo, 2015). With the features they have, they are among the best silicon solar cells to use for portable devices, building-integrated systems, or just for projects that cover large areas. However, the efficiency of this technology typically falls between 6% and 10%. Currently, advancements like multi-junction structures and improved coating techniques are enhancing this efficiency (Kumar, 2017).

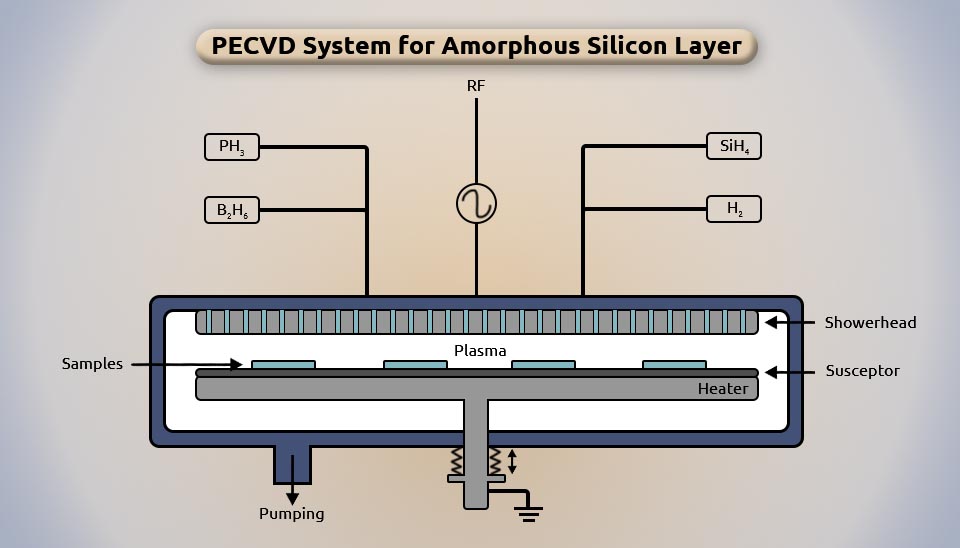

2.3.1. The Amorphous Silicon Cells Manufacturing Process

The amorphous silicon (a-Si) solar cells are manufactured in a different manner in comparison to the crystalline ones since they are not manufactured using crystal growth but instead through thin film deposition. Here a silicon layer extremely thin (typically less than a micrometer) is deposited over a substrate like glass or metal. Amorphous silicon (a-Si) is commonly deposited by plasma-enhanced chemical vapor deposition (PECVD) at low substrate temperatures of 150–300°C, where silane gas (SiH4) is decomposed by plasma, and the silicon atoms reach the substrate to be deposited as a uniform thin layer on the substrate (Singh & Goyal, 2021). The schematic of the process of depositing a-Si:H using PECVD is presented in the figure below. Under this technique, gases like SiH4 and H2 are injected into the chamber and broken down by the plasma. The subsequent reactive species reacts with the surface of the substrate to create the silicon layer (Morisset, 2019).

2.3.2. Advantages of the Amorphous

Amorphous silicon photovoltaic cells are superior in affordability and versatility. Thin-film design makes them low-cost with methods such as plasma-enhanced chemical vapor deposition, using far less silicon material—typically only 1-2 μm thick— than the thicker crystalline silicon wafer (Bharam, 2012). In addition to the common advantages of silicon solar cells, amorphous thin-film technology also provides the unique benefit of flexibility and lower production costs, making it suitable for building-integrated systems and portable applications (Sarkar & Gosh, 2017). These materials are effective in diffuse or low radiation situations due to their high absorption coefficient, and they exhibit better temperature tolerance, with efficiency reducing by only 0.2-0.25% for each degree Centigrade above 25°C (Kang, 2021). Environmentally wise, they are non-toxic and more environment-friendly and do not consume many resources.

2.3.3. Disadvantages of the Amorphous

Though amorphous silicon (a-Si) solar cells are very positive in many regards, their cons are also significant. Efficiency is typically between 5 and 12%, which is far less than the 15–25% offered by crystalline silicon cells, and therefore they are not categorized as high-efficiency silicon solar cells (Pastuszak & Węgierek, 2022). Larger installation spaces are thus required to yield the same power output levels. Additionally, the cells are affected by the Staebler–Wronski effect in that light exposure first reduces efficiency by anywhere from 10–30% or more prior to stabilizing to a lower level (Kang, 2021). Other performance drawbacks include the relatively short silicon solar panel lifespan of about 15 years, along with lower minority carrier lifetimes and ineffective doping. All in all, these all contribute to capping the performance offered by the a-Si cells as well as their usage in cases of high demand or large volumes (Bharam, 2012).

2.4. Advanced Silicon-Based Technologies

Silicon solar cell technology hasn’t stayed at the traditional monocrystalline, polycrystalline, and amorphous. Recent years have seen emerging silicon technologies with the mission to increase performance, lower costs, and expand applications. Some of the main improvements include passivated emitter and rear cells (PERC), bifacial modules, and tandem silicon–perovskite cells, where a perovskite layer is combined with silicon to enhance the efficiency of silicon solar cells and enable better utilization of the solar spectrum.

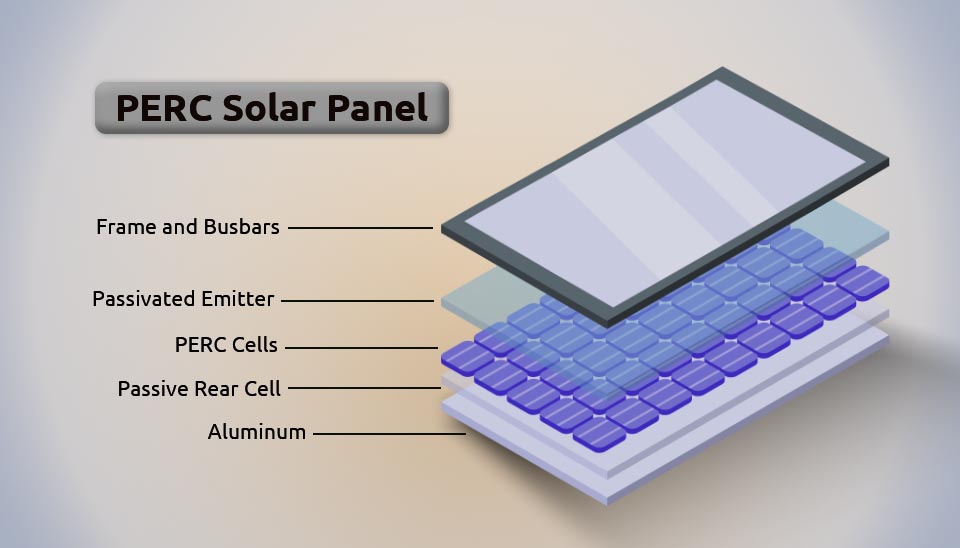

2.4.1. PERC Silicon Cells

PERC is one of the most promising breakthroughs in conventional silicon solar cells in years. With the addition of a dielectric passivation layer on the rear side of the cell, electron recombination is reduced, and more light is trapped back into the silicon wafer. The architecture is also designed to maximize light absorption and usually improves the efficiency of silicon solar cells by 1–2% over standard silicon cells (Pastuszak & Węgierek, 2022).

Advantages:

- We can achieve enhanced efficiency with minimal change in design.

- This product is well-suited for both residential and commercial installations.

- The cost reduction is due to its compatibility with existing production lines.

Disadvantages:

- The product is slightly more complicated to produce.

- The material is sensitive to light-induced degradation (LID) if it is not optimized.

2.4.2. Bifacial Silicon Cells

Bifacial silicon solar cells are monofacial cells featuring an open back surface with a dielectric passivation layer and in place of the standard polymer back cover, a transparent sheet is used. The two-sided operation can increase the overall energy output by 35–50%, depending on the design of the installation and the reflectance of the ground (Joseph et al., 2025).

Advantages:

- There is a greater annual energy yield per square meter.

- It works best in reflective or snowy conditions.

- longer silicon solar panel lifespan, which results from the use of more robust encapsulation materials.

Disadvantages:

- The initial cost is higher than that of normal panels.

- The system requires optimized mounting systems for maximum rear-side gain.

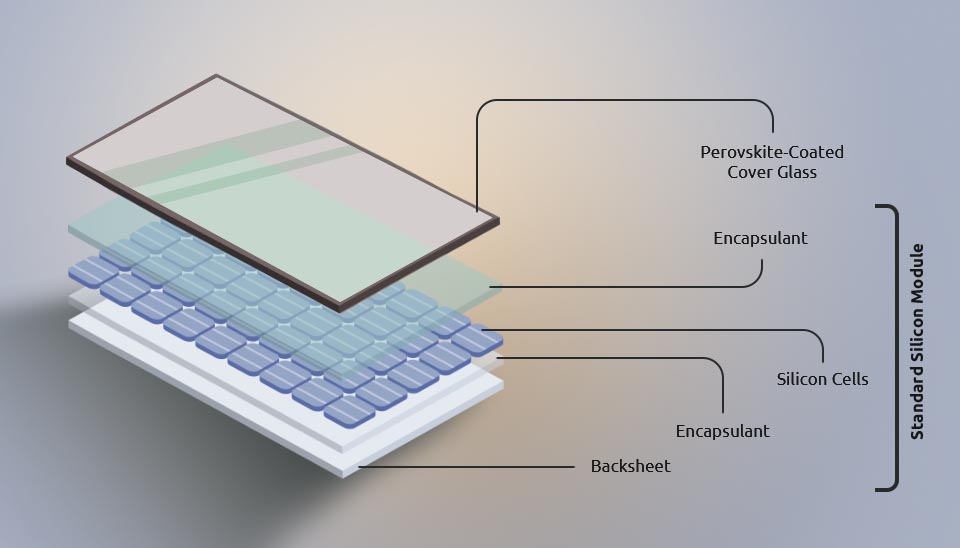

2.4.3. Silicon–Perovskite Tandem Cells

Tandem design is largely considered to be the future of silicon photovoltaics and a key step toward developing high-efficiency silicon solar cells. For tandem design, a perovskite layer is deposited atop a silicon wafer in thin layer form, enabling the cell to absorb more solar radiation with a larger band gap.Laboratory tests have demonstrated that this technology can achieve more than 30 percent efficiency of silicon solar cells, surpassing the Shockley–Queisser limit of single-junction silicon cells (Wang et al., 2023).

Advantages:

- There is a potential for record-breaking efficiency.

- Complementary absorption can be used to better utilize the solar spectrum.

- It is applicable to high-performance applications and space-constrained projects.

Disadvantages:

- Higher cost of manufacture and complex fabrication process.

- The perovskite layers are very difficult to stabilize and maintain long-term.

2.5. A Comparison of Different Types of Silicon Solar Cells

Currently, monocrystalline, polycrystalline, and amorphous (a-Si) are the most commonly found types of solar silicon cells. More recently there has been an increase in Advanced silicon technologies like PERC, Perovskite and bifacial cells. Thus, we compare these categories in the next section in terms of efficiency, cost and applications among others.

2.5.1. Performance Comparison

Solar cell efficiency is an important parameter that specifies how effectively it converts solar energy to electrical energy. Monocrystalline panels are usually the most efficient among widely used commercial technologies, with typical module efficiencies of 18–24% and laboratory single-junction cell efficiencies can be as high as 26.7% (Green et al., 2022). On the other hand, polycrystalline panels generally have lower efficiency rates, with an average of 15-18% (Schindler et al., 2018). Amorphous silicon thin-film solar cells made from amorphous silicon are in another class of efficiency, rated between 6% and 10% in commercial modules (Intal, 2025).

Under sunny conditions, experimental data indicates that monocrystalline panels surpass others in overall efficiency (Ayadi et al., 2022).

Advanced silicon technologies demonstrate further advancements: PERC offers further rear-side passivation, offering higher efficiency than typical monocrystalline cells; bifacial modules generate supplementary power from the rear side depending on albedo and mounting configuration; and tandem perovskite–silicon cells have recently achieved record efficiencies exceeding 30% in laboratory conditions, offering a promising pathway to surpass the theoretical limits of single-junction silicon (LONGi, 2025).

2.5.2. Cost Comparison

Conventional silicon-based technologies Monocrystalline panels have long been the most costly choice among conventional technologies because of their energy-intensive production process and increased efficiency. Technology however has made great strides thus narrowing the price gap between monocrystalline and polycrystalline panels. Historically, the price of polycrystalline panels was low, capturing a large share of residential solar market space, although the relative difference from monocrystalline panels is reducing. Lastly, thin-film panels are the most inexpensive option but are less efficient, consume more space, and depreciate quicker.

Most of the advanced technologies, such as PERC, bifacial, and new perovskite tandem cells, are typically more expensive to install than traditional monocrystalline and polycrystalline modules. PERC involves more processing, bifacial modules are more complex to manufacture and install, and perovskite tandem is expensive today in pilot-scale manufacturing, and issues of stability. However, by delivering high energy yield per unit area and reducing the levelized cost of electricity (LCOE) across the lifetime of the system, particularly in large scale or space-constrained systems, the technologies can greatly contribute to the economics of a project.

2.5.3. Appearance and Aesthetic Comparison

The most aesthetically refined is typically the thin-film panels, which have a homogeneous black finish and have very little visible cabling, giving them a sleek, modern look. Their disadvantage is that they are less efficient and they are likely to occupy more space during installation. Monocrystalline panels also have a glossy black appearance, only that the clear outlines of the cell shapes form conspicuous white areas. Monocrystalline panels also possess a shiny black look, but the distinct delineation of their cell forms creates conspicuous white spaces. While they possess a stylish look, they tend to be more conspicuous than thin-film panels. Polycrystalline panels are among the less popular types of silicon solar panel, mainly due to their lower efficiency compared to monocrystalline options. Instead of the blue, marbled look being consistent from module to module, each module is unique, providing a less uniform and less good-looking appearance (solarreviews.com).

Advanced silicon modules are visually close to conventional silicon modules but with notable variations: PERC cells look nearly identical to monocrystalline panels, bifacial modules often use glass on both sides or transparent backsheets that create a distinctive appearance, and perovskite tandem devices can integrate semi-transparent or colored layers, opening possibilities for building-integrated photovoltaics (BIPV) where aesthetics are critical.

3. Conclusion

Dominating more than 90% of the globe’s market share of solar panels, silicon-based solar cells are the foundations of solar production of energy by dint of their unmatched versatility and scalability from small appliance-sized objects to large-sized electric-power stations. There are three main types of silicon solar panel: monocrystalline (high efficiency but higher cost), polycrystalline (moderate efficiency and lower cost), and amorphous (flexible, cheaper but less efficient), all of which are based on the photovoltaic effect. To overcome the limitations of these standard types, advanced technologies have emerged, such as PERC cells, bifacial cells, and silicon–perovskite tandem cells, which enhance performance and energy absorption, achieving efficiencies of over 30%. However, the selection of the type of silicon solar cells to be used is determined by a number of factors, which include; the budget, the space at hand, the required efficiency and the environmental conditions. After all, as the solar energy revolution has persisted and thrived on a five-decade history and excellent research backgrounds, silicon will still be the foundation of the solar energy revolution. The advantages of silicon solar cells, such as high availability, versatility, and ongoing innovation, ensure their central role in shaping the renewable energy landscape. Awareness of these advantages and disadvantages of silicon solar cells helps investors, researchers, and policymakers make more informed decisions.

Author: Sobhan Fakhar Noghani

M.Sc. in Renewable Energy Engineering, University of Tehran

Email: Sobhan.fakhar@ut.ac.ir

🔗 LinkedIn

🔗 ResearchGate